Back to Homepage

SYSTEMS

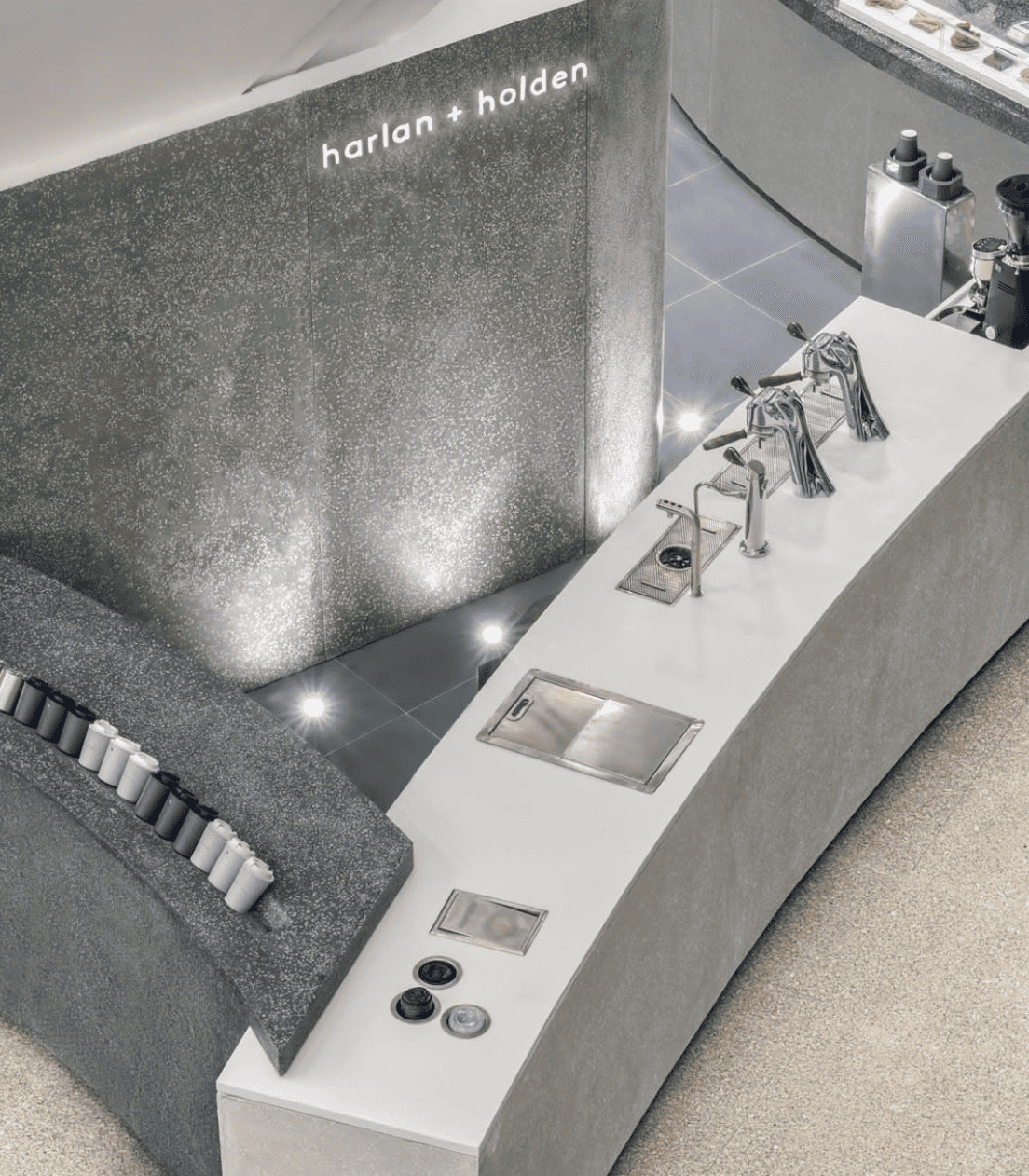

Concrete Polishing System®

Shaped by vision, defined by design, and committed to quality. Every project is a canvas. Every detail, a statement.

The First of Its Kind In The Philippines

JVAZCO pioneered polished concrete in the Philippines, bringing global standards to local projects through its Concrete Polishing System® — aligned with the U.S. Concrete Polishing Council (CPC) and built to deliver unmatched results.

FEATURES

What sets this system apart

From matte to gloss—tailored to your needs

The Concrete Polishing System® follows a structured process defined by finish levels—CPS1 to CPS7—each one measurable, repeatable, and aligned with international CPC standards to match the desired polishing.

Built for durability and sustainability

Certified by LEED©, NSF©, and SCS©, this system offers proven sustainability. Engineered to outlast epoxy, tiles, and other topical coatings, it delivers superior abrasion resistance and non-slip performance for enhanced safety and durability.

Quality without compromise

At JVAZCO, every project is a commitment to excellence. Skilled craftsmen apply their expertise with precision, using only the best materials and equipment. Each step adheres to rigorous industry standards, ensuring durability, optimal performance, and enduring quality.

Logistics Warehouse

Concrete Polishing System

JVAZCO delivered 26,042 square meters of polished concrete flooring for a global logistics warehouse in Sta. Rosa, Laguna, achieving a high-gloss, durable finish designed for heavy forklift traffic and 8–11m high racking systems. Through a multi-stage grinding, honing, and polishing process, the floor was refined to meet exacting operational demands — enhancing durability, reducing maintenance, and improving light reflectivity for a brighter, more efficient workspace. This project reflects JVAZCO’s leadership in polished concrete solutions for high-volume, performance-driven facilities.

Concrete Flatwork System® and Concrete Polishing System®

CPS and CFS are built to work seamlessly together—CFS lays the precision-flat foundation, while CPS builds on it with polished performance. The result: a surface that’s level, durable, and finished to perfection.

featured article

Concrete for Endless Possibilities

JVAZCO has added both GFRC and Architectural precast production to their repertoire, a new milestone for the company as we end the year. As the official distributor of RECKLI formliner in the Philippines

Read More

Concrete Systems

Complete systems behind high-quality concrete work

Learn more about our concrete solutions—built to work together or on their own for durable, high-quality output.

View All SystemsOur Offerings

Discover products that last

Discover the coatings, finishes, and curated products that elevate every surface.

Designers’ Selection

Premier design and construction solutions to elevate every space and project

Specialty Products

Concrete product solutions for custom finishes and surfaces

FAQ

What You’re Wondering

Answers to the things you're probably wondering about.

What is concrete polishing?

Concrete polishing is the process of grinding, honing, and sealing concrete floors to achieve a smooth, shiny, and durable finish.

Why choose polished concrete?

Polished concrete is low-maintenance, long-lasting, and eco-friendly. It also enhances the look of any space with a modern and clean finish.

Where can polished concrete be used?

It’s perfect for homes, offices, showrooms, restaurants, warehouses, and any space that needs both durability and style.

Can old concrete floors be polished?

Yes, as long as the concrete is structurally sound.

What look or finish options are available?

A. You can choose from matte, satin, or high-gloss finishes depending on your style and preference.

B. Finish Options

I. Cream Finish – Smooth and uniform look.

II. Salt-and-Pepper Finish – Speckled with small stone particles.

III. Exposed Aggregate Finish – Bold look with larger stones visible.

B. Finish Options

I. Cream Finish – Smooth and uniform look.

II. Salt-and-Pepper Finish – Speckled with small stone particles.

III. Exposed Aggregate Finish – Bold look with larger stones visible.